Azienda

Ogni giorno miliardi di persone utilizzano prodotti, servizi ed energia generati dal contributo invisibile di numerose aziende. Il video fornisce uno spaccato sul lavoro quotidiano delle nostre persone e su come il loro impegno ha contribuito e continuerà a contribuire alla vita quotidiana delle persone in tutto il mondo.

Prodotti

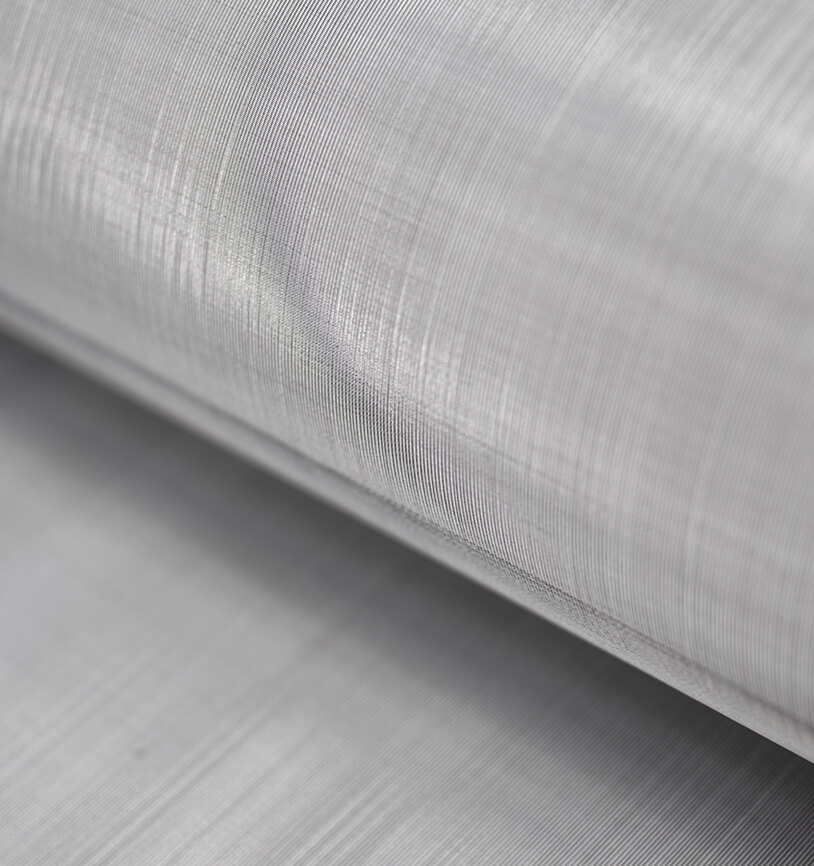

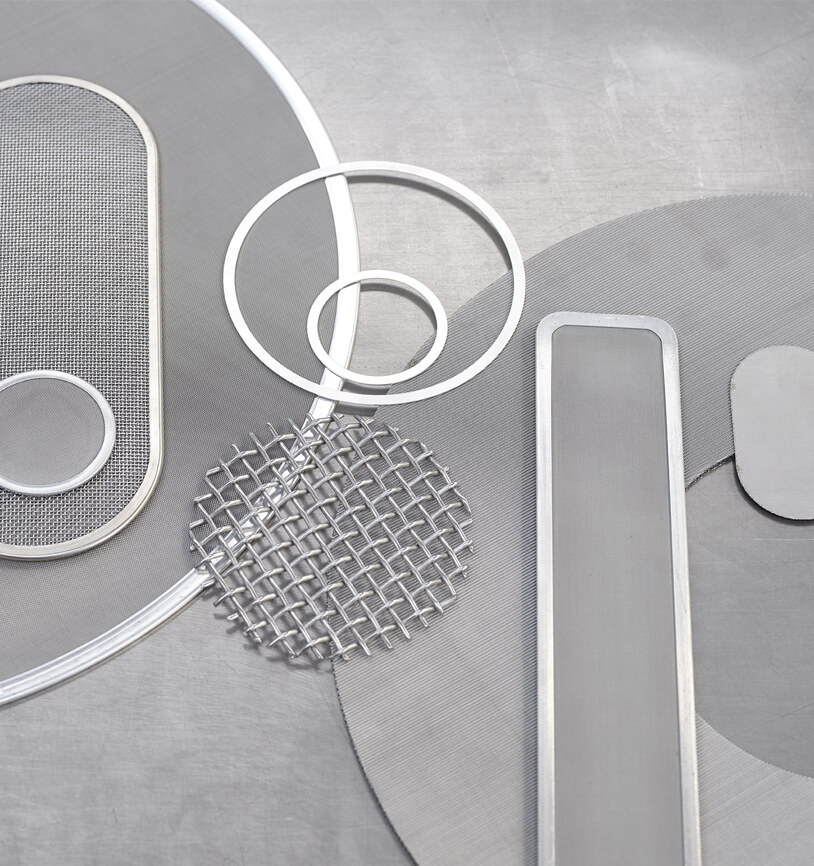

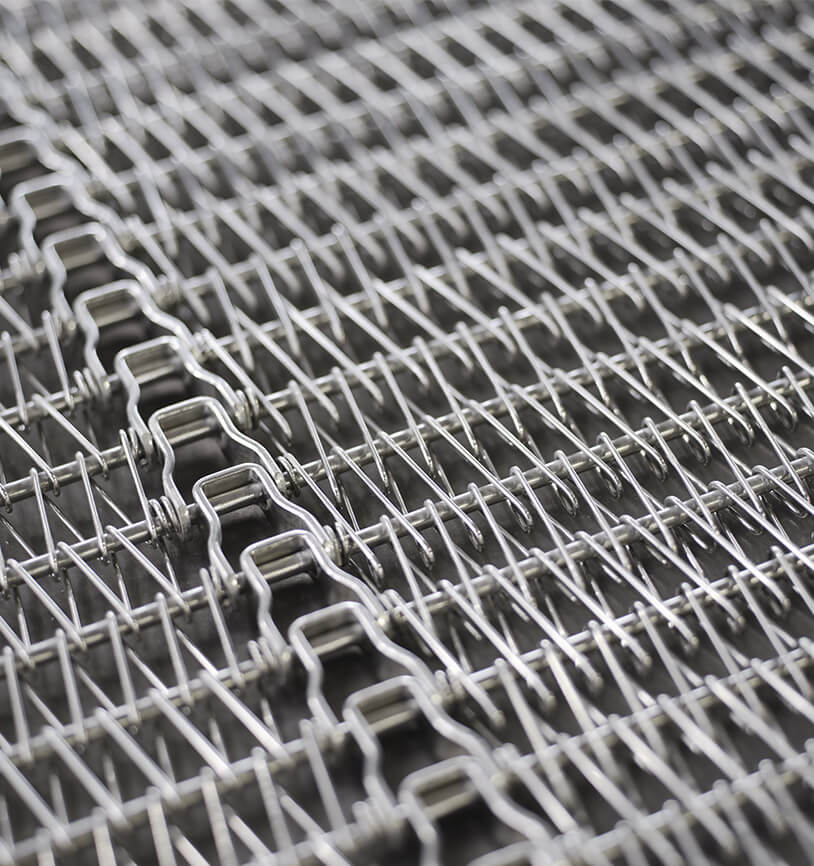

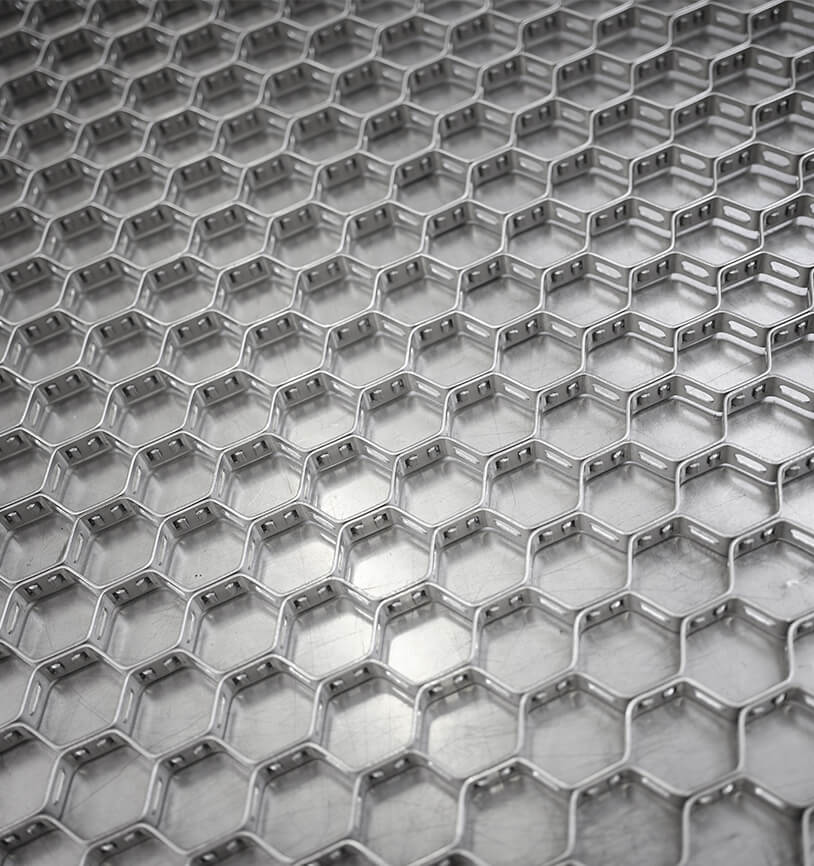

Costacurta realizza ogni suo prodotto partendo da fili e lamiere di diversi diametri, spessori e tipologie di acciai e leghe speciali,

applicando da sempre le più moderne ed efficienti tecnologie di produzione, nel rispetto di tolleranze molto stringenti.

Applicazioni

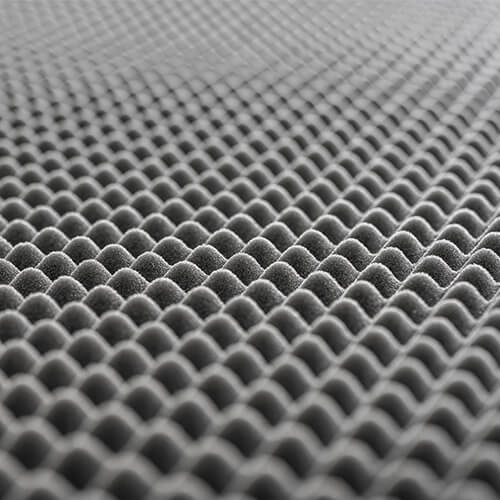

Ciascuna linea prodotto viene utilizzata in differenti industrie e, nell’ambito di ciascuna Industria, in numerose applicazioni.

Le Industrie Petrolifera, Petrolchimica, Metalmeccanica, Siderurgica, Alimentare sono le principali servite.